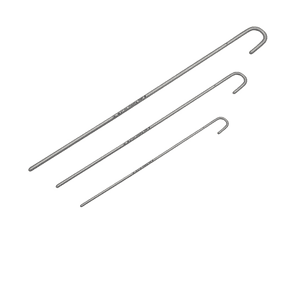

A medical stylet is a small, malleable plastic-coated metal rod most commonly used in endotracheal (ETT) devices for intubation. They are a medical component that is placed inside an endotracheal tube to reinforce or pre-shape the lumen of the tube to aid in directing the tube towards the laryngeal inlet. As with any medical device or medical component, production of medical stylets is a result of a combination of design, engineering, materials science, and state-of-the-art manufacturing facility. Production standards must also meet FDA regulatory requirements for medical devices. The FDA classifies medical devices by three regulatory classifications: I, II, and III, with Class I having lower risks associated with the safety and effectiveness of the device or component (with Class III having the highest risks). Medical stylets are listed under Device Class I by the FDA for use in tracheal tubes.

A medical stylet is a small, malleable plastic-coated metal rod most commonly used in endotracheal (ETT) devices for intubation. They are a medical component that is placed inside an endotracheal tube to reinforce or pre-shape the lumen of the tube to aid in directing the tube towards the laryngeal inlet. As with any medical device or medical component, production of medical stylets is a result of a combination of design, engineering, materials science, and state-of-the-art manufacturing facility. Production standards must also meet FDA regulatory requirements for medical devices. The FDA classifies medical devices by three regulatory classifications: I, II, and III, with Class I having lower risks associated with the safety and effectiveness of the device or component (with Class III having the highest risks). Medical stylets are listed under Device Class I by the FDA for use in tracheal tubes.

Medical stylets then are an important component for endotracheal (ET) intubation devices. The process of endotracheal intubation requires precision. The procedure entails inserting a tube through a patient’s mouth and into their trachea (the windpipe) to assist in their breathing during anesthesia, sedation, or severe illness. Without a stylet within the lumen of an endotracheal tube, the plastic tubing could be too flexible for intubation. The stylet’s malleability allows for a sufficient degree of flexibility for placement of the plastic tube through the mouth into the trachea. The clear, plastic coated sheath of the stylet is designed for its tips to fit within the lumen, not to protrude from it. Once the endotracheal tube is in place it is connected to a ventilator, which delivers oxygen to the lungs.

There are several reasons for endotracheal intubation procedures, including surgery or trauma, but the main purpose of endotracheal intubation use is when a patient cannot or is unable to breathe on their own. ETTs are utilized by doctors or paramedics to create an airway and to ventilate an injured person. For paramedics, the most common ventilating system is an endotracheal (ET) intubation device for use in the field on trauma patients. The stylet is already in place within the lumen of the tubing for emergency endotracheal intubation. Medical stylets are also used in intubation of seriously ill patients who require sedation. The procedure maintains the airway for air to pass into and out of the patient’s lungs.

Production of medical stylets, like any smaller medical components, is a result of developments in materials science and precision manufacturing of medical devices. Structure, properties, and processing are key factors to determine the performance of the material. Medical components, in general, must be able to meet performance requirements that may include strength, durability, minimal thickness, or microbial resistance. The components must also meet FDA regulatory requirements and appropriate international standards (when applicable).

To adhere to regulatory requirements as well as production needs, the metals used in medical stylets must have properties such as high ductility and malleability, and must especially be corrosion resistant. Because of the latter, stylets are generally manufactured with grade 316 stainless steel. Referred to as medical or surgical grade stainless steel, grade 316 is widely used in biomedicine in a range of devices from surgical implants to instruments. Known for its high levels of purity and cleanliness, just as importantly, grade 316 does not cause a reaction with living tissue.

At James Spring & Wire we recognize that medical stylets are an important component in the manufacturing of endotracheal (ET) intubation devices. As an original equipment manufacturer (OEM) of customized medical devices and components, James Spring & Wire provides medical grade stainless steel stylets among other products for the medical and biotech industries. Our state-of-the-art manufacturing facility produces the highest quality products available and allows for total quality control over the manufacturing of your product.