In precision metal stamping, a part is either right—or it is rejected. There’s no middle ground when components have to fit, flex, and perform reliably in critical assemblies. That’s why quality control is at the center of every successful precision metal stamping process.

From material selection to final inspection, robust quality control measures protect your designs from variability, reduce scrap, and ensure consistent performance in the field. For manufacturers that rely on stamped parts, that translates directly to fewer failures, smoother assembly, and a more predictable supply chain.

From material selection to final inspection, robust quality control measures protect your designs from variability, reduce scrap, and ensure consistent performance in the field. For manufacturers that rely on stamped parts, that translates directly to fewer failures, smoother assembly, and a more predictable supply chain.

James Spring & Wire stands at the intersection of precision-stamped components, springs, and wire forms, where tight tolerances, repeatability, and functional performance are non-negotiable.

Quick Answer: What Quality Control Measures Matter Most in Precision Metal Stamping?

Quality control in precision metal stamping focuses on material verification, tooling condition, in-process inspection, dimensional measurement, surface and burr control, and final functional testing. Together, these measures ensure stamped parts meet specified tolerances, perform reliably in service, and arrive ready for assembly with minimal rework or scrap.

What Is Precision Metal Stamping?

Precision metal stamping uses dies, presses, and carefully controlled processes to produce high volumes of metal components with consistent dimensions. Typical outputs include:

- Brackets and clips

- Electrical and mechanical contact components

- Strip forms and stampings integrated with springs and wire forms

Because these parts often interface with other components or assemblies, even small dimensional or surface deviations can create fit issues, premature wear, or performance failures. Quality control ensures that each part leaving the press matches the design intent—not just nominal dimensions.

Why Quality Control Is Critical in Metal Stamping

Inadequate quality control can lead to:

- Increased scrap and rework

- Assembly line disruptions

- Field failures and warranty claims

- Higher total cost per part

Effective quality programs in stamping operations focus on:

- Preventing defects, not just detecting them

- Stabilizing processes so parts remain in control over long runs

- Documenting performance so customers can trust each shipment

This is especially important when stampings interface with springs and wire forms, where material behavior under load, stress, and fatigue is critical.

Material Verification and Incoming Inspection

Every quality stamping process starts with the right material. If the material is off, everything downstream is at risk.

Key material-related checks include:

- Material certification review – Verifying grade, chemistry, and mechanical properties agree with specifications.

- Thickness and flatness checks – Ensuring coil or strip thickness and flatness are within tolerance for the die design.

- Surface condition – Checking for scale, scratches, or contamination that could affect forming, coating, or conductivity.

By confirming material integrity up front, stampers reduce variability and avoid surprises later in forming, bending, or coining operations.

Tooling Condition and Die Maintenance

Precision metal stampings are only as accurate as the tools that form them. Worn or damaged tooling will show up immediately in part quality.

Effective quality control includes:

- Scheduled die inspections – Checking cutting edges, forming features, and clearances.

- Preventive maintenance – Sharpening, polishing, and replacing wear components before they impact parts.

- Alignment verification – Ensuring dies and presses are properly aligned to prevent uneven wear and dimensional drift.

Consistent tooling condition helps maintain stable processes and predictable part dimensions over the full life of the die.

In-Process Inspection and Statistical Process Control

Rather than waiting for the end of a run, high-performing stampers use in-process inspection to catch issues early.

Common practices include:

- First-article inspections – Validating a new setup against drawings and requirements before releasing production.

- Periodic sampling during runs – Measuring critical features at defined intervals.

- Statistical Process Control (SPC) – Tracking characteristic measurements over time to detect trends and correct processes before parts go out of tolerance.

For critical stampings that work with springs or wire forms, in-process controls help maintain consistent forces, deflections, and engagement points from part to part.

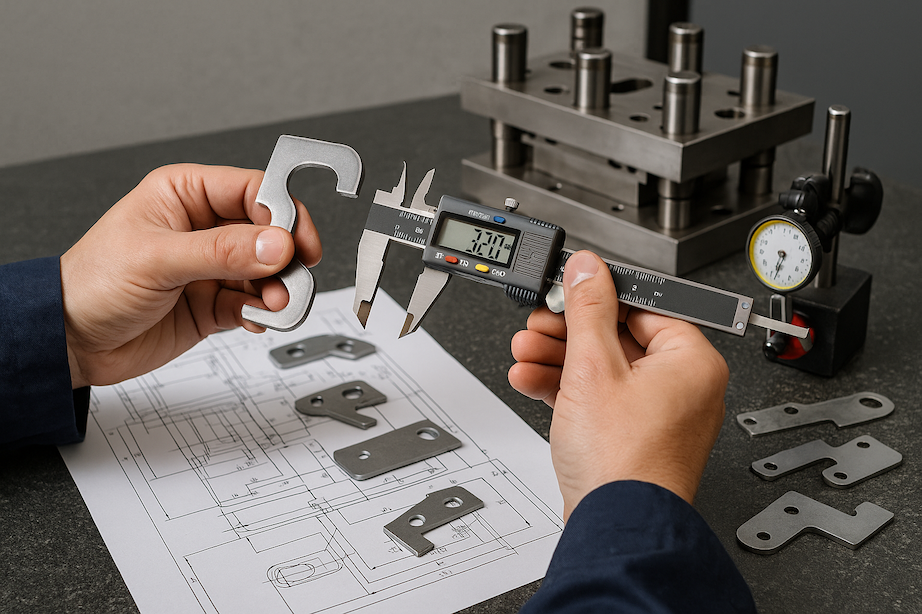

Dimensional Inspection and Measurement Techniques

Dimensional accuracy is central to precision metal stamping. Quality teams use a mix of manual and automated tools, such as:

- Precision calipers and micrometers

- Go/no-go gauges and functional gaging

- Optical comparators and vision systems

- Coordinate Measuring Machines (CMM) for complex geometries

These tools verify:

- Overall dimensions

- Hole sizes and locations

- Bend angles and radii

- Flatness and parallelism

By focusing on critical-to-function features, stampers ensure that parts assemble correctly and perform as required.

Surface Quality, Burr Control, and Edge Condition

Even when dimensions are correct, poor surface conditions can cause problems in downstream operations.

Quality control in this area typically addresses:

- Burr height and edge condition – Managing burrs to avoid cutting, scraping, or interference in assemblies.

- Surface finish – Ensuring surfaces are smooth enough for sealing, coating, or electrical contact.

- Deburring and finishing processes – Applying tumbling, brushing, or other methods consistently and verifying results.

These measures are especially important where stampings interface with moving components, springs, or sensitive surfaces.

Functional and Performance Testing

For many precision stampings, functional performance matters as much as raw dimensions. Quality control may include:

- Fit and assembly checks – Verifying that parts seat, engage, or latch correctly with mating components.

- Load and deflection testing – Ensuring components that flex, support or retain loads behave as designed.

- Retention or clip force checks – Confirming that stamped clips, brackets, or retaining elements hold parts securely without damage.

By validating function as well as form, stampers help reduce the risk of performance issues in real-world applications.

Documentation, Traceability, and Certifications

Quality control also extends into documentation and traceability. Manufacturers increasingly expect:

- Documented inspection plans and results

- Lot traceability back to material and process conditions

- Adherence to relevant quality standards and customer-specific requirements

A disciplined approach to documentation builds confidence, supports audits, and makes it easier to investigate and correct any issues that may arise.

How We Support Quality in Precision Metal Stamping

As a manufacturer of springs, strip forms, stampings, and wire forms, James Spring & Wire understands how stamped components must work in concert with other precision parts.

Their approach to quality control in metal stamping emphasizes:

- Collaboration between engineering and production to define the right material, tolerances, and inspection criteria

- Careful tooling design and maintenance to support repeatable high-volume production

- In-process inspection and functional checks to ensure components work as intended in the final assembly

Whether you need a standard stamped component or a custom solution integrated with springs and wire forms, a strong quality control process ensures consistency from prototype through full production.

If you rely on stamped components in critical assemblies, the right manufacturing partner can make quality control a competitive advantage. Talk with the team at James Spring & Wire about your precision metal stamping requirements, quality expectations, and long-term production goals.

Frequently Asked Questions

What are the most important quality control steps in precision metal stamping?

Key steps include material verification, tooling inspection, in-process dimensional checks, burr and surface control, and final functional testing to confirm that parts perform as designed.

How does material selection affect stamping quality?

Material type, thickness, and surface condition all influence formability, springback, and dimensional stability. Verifying material properties up front helps ensure the process produces consistent, in-tolerance parts.

Why is in-process inspection important in metal stamping?

In-process inspection detects variation or drift while parts are still being produced. This allows adjustments before issues turn into large quantities of nonconforming parts or assembly problems.

What tools are used to measure precision stampings?

Measurement tools can include calipers, micrometers, gauges, optical comparators, and coordinate measuring machines. The tools selected depend on the complexity and tolerances of the part.

How do stampers ensure burrs and edges are controlled?

Stampers control burrs through proper tooling design, die maintenance, and consistent finishing processes. Burr height and edge conditions are typically checked as part of regular inspection plans.