When it comes to custom metal components, few solutions offer the adaptability and performance of wire forms. At James Spring & Wire Company, we understand the importance of delivering precise, high-quality custom wire forms that meet the unique demands of various industries. From simple hooks to complex multi-axis geometries, wire forms are an essential part of custom metal fabrication across sectors like automotive, aerospace, and construction.

What Are Wire Forms?

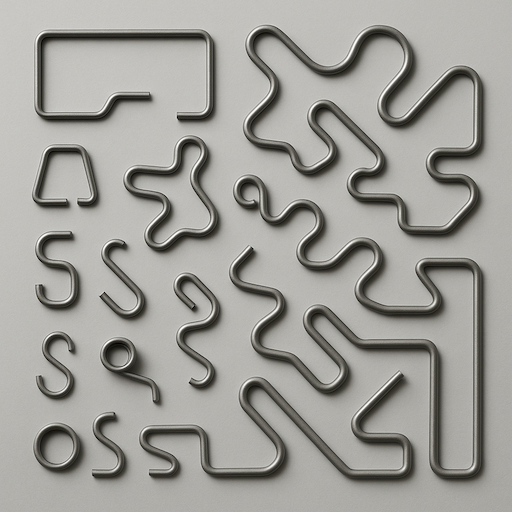

Wire forms are custom-shaped metal components made from wire that is bent, cut, and coiled into specific configurations. They serve both functional and structural roles in countless applications, from clips and brackets to springs and fasteners. With advanced CNC wire forming and expert engineering support, James Spring & Wire Company produces wire forms with tight tolerances and reliable repeatability.

Wire forms are custom-shaped metal components made from wire that is bent, cut, and coiled into specific configurations. They serve both functional and structural roles in countless applications, from clips and brackets to springs and fasteners. With advanced CNC wire forming and expert engineering support, James Spring & Wire Company produces wire forms with tight tolerances and reliable repeatability.

Versatility Across Industries

One of the primary advantages of wire forms is their ability to be customized for industry-specific needs.

- Automotive: In the automotive sector, wire forms are used in seats, latches, and engine components. Their lightweight yet durable properties contribute to vehicle efficiency and performance. Learn more about our solutions for the automotive industry.

- Aerospace: Aerospace applications demand high precision and performance. Wire forms meet these challenges in areas like avionics assemblies and vibration-dampening components. We offer materials and finishes suitable for extreme environments. Explore our aerospace capabilities.

- Construction: In construction, wire forms play a role in framing supports, rebar ties, and electrical systems. Their adaptability and ease of integration make them ideal for dynamic job site conditions. Discover our construction industry offerings.

Customization & Design Flexibility

Custom wire forms can be produced in an array of shapes, sizes, and materials, including stainless steel, carbon steel, and specialty alloys. This flexibility allows engineers and designers to develop components that meet specific load, space, and environmental requirements.

At James Spring & Wire Company, we collaborate with customers to create wire forms tailored to their project specifications. Our in-house tooling and design capabilities help shorten lead times and enhance product quality.

Cost-Efficiency and Scalability

Another key benefit of wire forms is cost-efficiency, especially in large-volume production. Our advanced forming equipment enables high-speed, automated production without compromising quality. This makes wire forms an economical choice for both prototyping and mass manufacturing.

Trust a Proven Partner in Wire Form Manufacturing

James Spring & Wire Company brings decades of experience in precision wire forming. Whether you need a custom prototype or a full production run, our team is ready to help you design and manufacture wire forms that meet your application needs. View our full range of wire form products.

Ready to explore how custom wire forms can support your next project? Contact us today to get started with our expert engineering team.